- Description

- Inquiry

- Attachment

Description

GYDTS-360Xn Optic Cable is Loose sleeve stranded lightly armored optical fiber ribbon cable

GYDTS-360Xn Optic Cable Product Overview

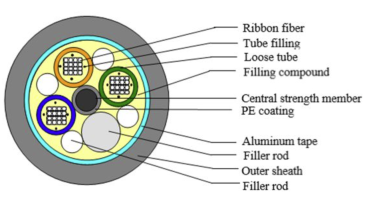

The structure of GYDTS fiber optic cable is to insert 4, 6, 8, and 12 fiber strips into a loose tube made of high–modulus material, and the loose tube is filled with waterproof compound. In the center of the core is a metal reinforcing core, and for some core cables, a layer of polyethylene (PE) is squeezed out of the metal reinforcing core. The loose tube (and filler rope) are twisted around the central reinforcing core to form a compact and rounded core, and the gaps within the core are filled with water-blocking filling. Double–sided plastic–coated steel tape (PSP) is longitudinally wrapped and extruded into a polyethylene sheath to form a cable.

GYDTS-360Xn Optic Cable Product Pictures

GYDTS-360Xn Optic Cable Product Specifications

| Fiber optic cable model (in 2-fiber increments) |

Number of fibers | Number of casings | Number of infill ropes | Reference cable weight (kg/km) | Tensile force is allowed Long-term/short-term (N) |

Allowable squashing force Long-term/short-term (N/100mm) |

Bend radius Static/Dynamic (mm) |

|

| GYDTS-48Xn | 4×12 | 1 | 3 | 306 | 600/1500 | 300/1000 | 10D/20D | |

| GYDTS-96Xn | 8×12 | 2 | 2 | 306 | ||||

| GYDTS-144Xn | 12×12 | 3 | 1 | 306 | ||||

| GYDTS-216Xn | 18×12 | 4 | 0 | 306 | ||||

| GYDTS-288Xn | 24×12 | 4 | 0 | 338 | ||||

| GYDTS-360Xn | 30×12 | 5 | 0 | 338 | ||||

| GYDTS-432Xn | 36×12 | 6 | 0 | 447 | ||||

| Fiber type | Attenuation (+20℃) | Bandwidth | Numerical aperture | Fiber optic cable cut-off wavelength | ||||

| @850nm | @1300nm | @1310nm | @1550nm | @850nm | @1300nm | |||

| G.652 | — | — | ≤0.36dB/km | ≤0.22dB/km | — | — | — | ≤1260nm |

| G.655 | — | — | ≤0.40dB/km | ≤0.23dB/km | — | — | — | ≤1450nm |

| 50/125µm | ≤3.3dB/km | ≤1.2dB/km | — | — | ≥500MHz·km | ≥500MHz·km | 0.200±0.015 NA | — |

| 62.5/125µm | ≤3.5dB/km | ≤1.2dB/km | — | — | ≥200MHz·km | ≥500MHz·km | 0.275±0.015 NA | — |

GYDTS-360Xn Optic Cable Product Features

- It has very good mechanical properties and temperature characteristics

- The loose tube material itself has good hydrolysis resistance and high strength

- The tube is filled with a special ointment to protect the optical fiber

- The specially designed tight cable structure effectively prevents the casing from retracting

- Good compression resistance and softness

- The PE sheath has very good resistance to ultraviolet radiation

- 4, 6, 8 and 12 fiber strips are used for flexible application

- The following measures are taken to ensure the waterproof performance of the fiber optic cable:

- Single steel wire center reinforcing core

- The loose tube is filled with a special waterproof compound

- Fully core filled

- Double-sided plastic-coated steel strip (PSP) improves the moisture permeability of fiber optic cables

GYDTS-360Xn Optic Cable Product and More Optic Cable

Loose sleeve stranded reinforced core armored flame retardant optical cable(GYTZA53)

Loose sleeve stranded non-metallic reinforced core armored flame retardant fiber optic cable (GYFTZA53)

Stranded Flame Retardant Fiber Optic Cable (GYTZS)

Stranded loose jacket non-armoured flame retardant fiber optic cable (GYTZA)

Stranded loose sleeve non-metallic reinforced core armored fiber optic cable (GYFTA53)

Stranded non-metallic reinforcing core plain armored fiber optic cable (GYFTY53)

Stranded loose jacket non-metallic reinforced core unarmoured fiber optic cable (GYFTA)

Loose sleeve stranded non-metallic reinforced core optical cable (GYHTY)

Stranded loose jacket non-metallic reinforced core unarmoured fiber optic cable (GYFTY)

Loose sleeve stranded single thin round steel wire armored fiber optic cable (GYTA53 33)

Loose Sleeve Stranded Reinforced Armoured Fiber Optic Cable(GYTA53)

Loose sleeve stranded ordinary armored fiber optic cable(GYTY53)

GYDTS-360Xn Optic Cable Product Applications

Application: pipeline, overhead, direct burial

GYDTS-360Xn Optic Cable Product Structure

Sorry, no attachment available !